Rising Sun & Rising Company,

We Are Solar Machinery Of Bharat India.

Products

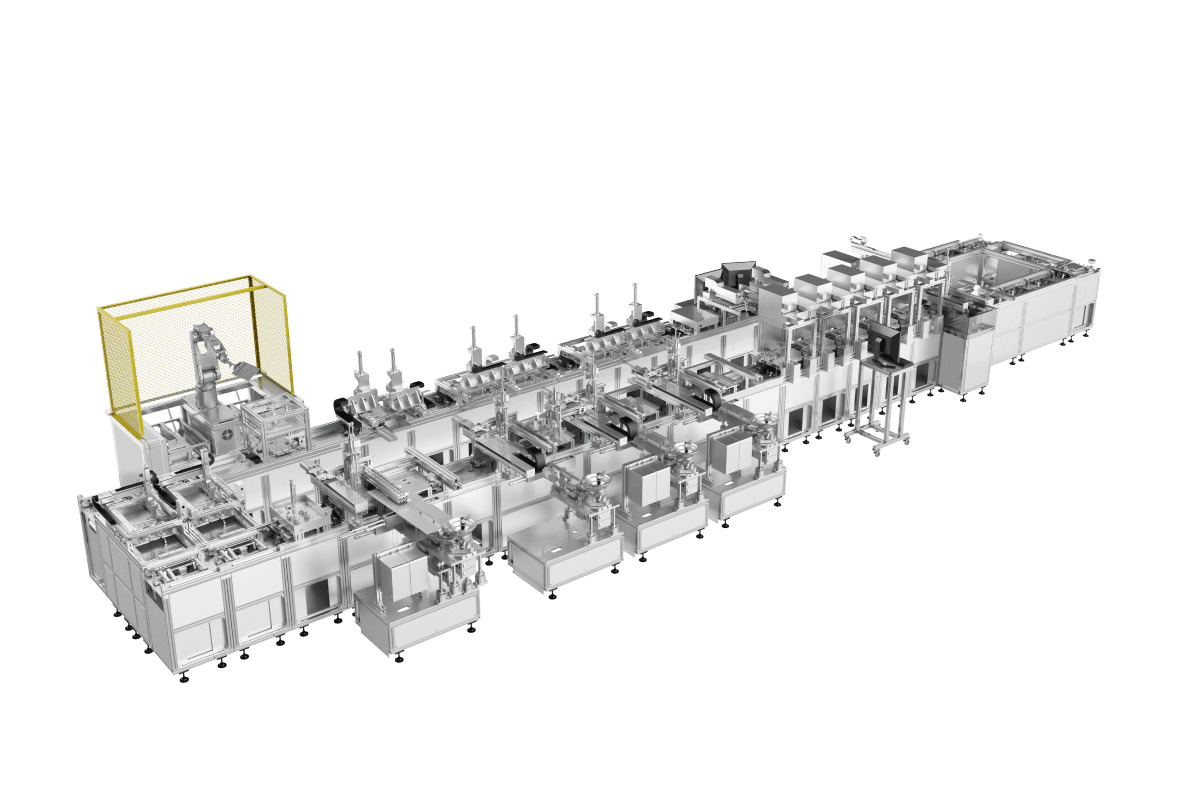

Become A World-class Leader In PV Automation Equipment

We specialize in production, and sales in four major areas photovoltaic production line equipment, turnkey projects for photovoltaic production lines, investment and operation of photovoltaic power stations, and intelligent of lithium battery equipment. We are a rising star in the new energy equipment industry. Through technological breakthroughs, improved production efficiency, and cost reduction, we are committed to creating higher value for customers through intelligent operations, precise control, and efficient output. With over a decade of experience in the photovoltaic industry, our company has a complete production base and sales service network.

Offering Technologies Which Provides Production Equipment For Photovoltaics: For Both Crystalline And Thin-Film High-Performance Solar Cell Platforms Including CIGS, CDTE And Perovskite Technology As Well As Perc, HJT, IBC, HBC & Topcon, Technologies Mixed With Experiences Will Improves Cell Efficiency And Reduces Costs For High-Performance Solar Cells.

Monocrystalline, Polycrystalline, Perc, Bifacial, Topcon, BIPV, HJT, Roof Tiles And Shingles, Transparent Solar Cell.

Robotic Solar Panel Cleaning Machine for Maintaining Photovoltaic Farms

Discover the state-of-the-art Solar Panel Cleaning Robot. This innovative and advanced robot offers an automated and efficient solution for maintaining and cleaning solar panels.

Equipped with two rotating nylon brush rollers and two section water spray nozzles, this robot ensures thorough cleaning of your solar panels. Its long water pipe allows for easy reach and coverage.

With cutting-edge technology and a high-efficiency cleaning mechanism, this robot guarantees optimal performance and longevity of your solar panels. Say goodbye to manual cleaning and let our advanced cleaning system take care of your solar panel maintenance needs.

Experience the future of solar panel maintenance with the Light-Weighted Solar Panel Cleaning Robot machine.